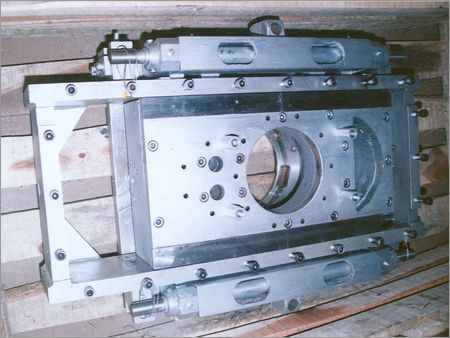

IPV Mechanism Assembly

Product Details:

- Technology Manual or Mechanical

- Power Source Manual / Mechanical Power

- Surface Treatment Corrosion Resistant Paint/Coating

- Control System Lever or Gear Operated

- Accessories Type Mechanical Linkage, Operating Rods, Fasteners

- Machine Type Isolator Mechanism

- Operating Pressure Ambient Atmospheric Pressure

- Click to View more

X

IPV Mechanism Assembly Product Specifications

- Mild Steel, Stainless Steel, Copper Alloy (as per component)

- Mechanically operate isolators or switches in electrical substations

- IPV (Individual Pole Operated) Mechanism Assembly

- Ambient Atmospheric Pressure

- High Voltage / Medium Voltage Switchgear, Substations

- Manual / Mechanical Power

- Manual or Mechanical

- Corrosion Resistant Paint/Coating

- Isolator Mechanism

- Mechanical Linkage, Operating Rods, Fasteners

- Applicable to 11kV, 33kV, 66kV or custom ratings

- Lever or Gear Operated

Product Description

IPV Mechanism AssemblyWe put forward a broad range of IPV Mechanism Assembly that is manufactured in adherence to the set industry standards using advanced technology and optimum quality components. Owing to high performance, less maintenance, operational fluency, easy usage, longer service life and cost-effectiveness, this IPV Mechanism Assembly is highly demanded in the global market. We offer this engineering machinery in different technical specifications at highly competitive prices.

Key Feature

- sturdy construction

- optimum elasticity

- precision engineered

- longer life service

- easy to maintain

- cost - effectiveness

- operational fluency

- less maintenance

- high performance

- easy usage

Exceptional Performance in Substation Operation

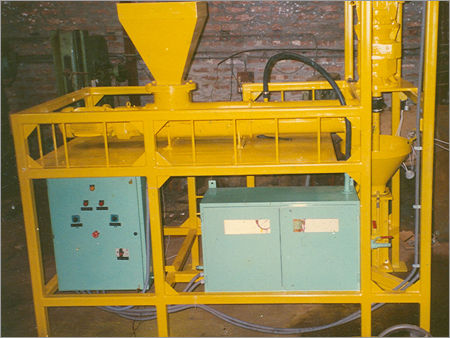

The IPV Mechanism Assembly is meticulously engineered to deliver reliable operation for isolators and switches in high or medium voltage substations. With corrosion-resistant finishes and robust materials, it ensures long-term service even in challenging atmospheric conditions. The mechanism can be operated manually or mechanically, offering flexibility in various installation scenarios and voltage levels.

Versatile Applications for Enhanced Control

Ideal for use with high voltage switchgear and electrical substations, this product supports a wide array of configurations, adapting to the specific voltage requirements and control setups. Its lever or gear-operated design, coupled with mechanical linkages, provides smooth and dependable operation. Accessories like operating rods and fasteners further enhance integration and performance.

FAQs of IPV Mechanism Assembly:

Q: How does the IPV Mechanism Assembly operate isolators in electrical substations?

A: The mechanism uses a lever or gear-driven control system connected to mechanical linkages and operating rods. When actuated manually or mechanically, these components transfer motion to isolate or connect electrical circuits, ensuring safe and controlled switching within substations.Q: What are the benefits of the corrosion-resistant treatment on the IPV Mechanism Assembly?

A: The corrosion-resistant paint or coating protects the assembly against harsh environmental conditions, moisture, and chemical exposure, significantly extending service life and reducing maintenance requirements in substation environments.Q: When should the IPV Mechanism Assembly be used in an electrical system?

A: It is best employed during the installation or maintenance of high or medium voltage isolators or switches, especially where manual or mechanical operation is required for reliable circuit isolation in switchgear and substation applications.Q: Where can the IPV Mechanism Assembly be installed?

A: The assembly is suitable for installation in both outdoor and indoor high or medium voltage substations and switchgear setups, particularly where mechanical operation of isolators is necessary.Q: What materials are utilized in constructing the IPV Mechanism Assembly?

A: Depending on the specific component, the mechanism uses mild steel, stainless steel, or copper alloy, each chosen for their strength, conductive qualities, and resistance to environmental stress.Q: How does the assembly support different voltage ratings like 11kV, 33kV, or 66kV?

A: The design is adaptable and can be configured for various voltage requirements, ensuring compatibility and optimal safety performance for 11kV, 33kV, 66kV, and other custom ratings as needed by the electrical system.Q: What are the main accessories supplied with the IPV Mechanism Assembly?

A: Standard accessories include mechanical linkages, operating rods, and fasteners, all of which are essential for seamless installation and operation of the isolator mechanism within substations and switchgear units.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Engineering Machinery' category

We are offering our products All over India and in Bangladesh, Sri Lanka, Nepal, Bhutan, Middle East, and South Africa.

Send Inquiry

Send Inquiry Send SMS

Send SMS