Engineering Components

Product Details:

- Machine Type CNC Milling, Turning, Assembly Units

- Features Corrosion Resistance, High Durability, Excellent Surface Finish

- Control System PLC / Manual

- Operating Pressure Up to 16 bar

- Power Source Electric

- Surface Treatment Anodized / Powder Coated

- Technology CNC Machining

- Click to View more

X

Engineering Components Product Specifications

- Corrosion Resistance, High Durability, Excellent Surface Finish

- PLC / Manual

- CNC Milling, Turning, Assembly Units

- Industrial Machinery, Automation Systems

- Precision Fitting and Motion Transfer

- Anodized / Powder Coated

- Up to 16 bar

- Electric

- 0.01 mm

- Mechanical Component

- Bearings, Shafts, Bushings

- CNC Machining

Product Description

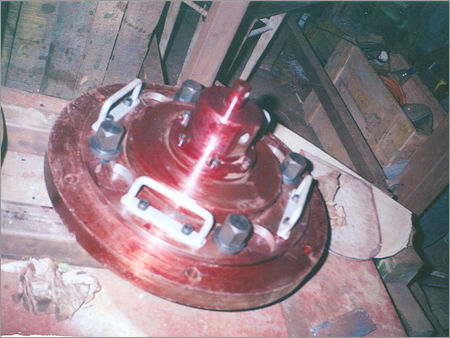

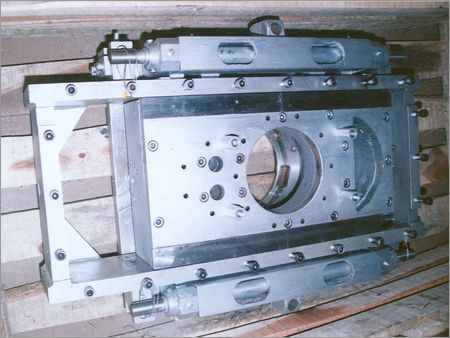

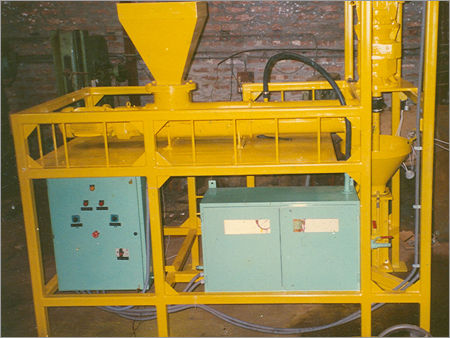

Every manufacturing machine to work reliably and hassle freely require good quality components. Keeping in mind the demand of good quality components, we manufacture Engineering Components of various sizes and designs, to suit diverse applications in machines. Precision engineered and easy installation are main features of our offered components.

Cutting-Edge Manufacturing Technology

Employing precision CNC machining techniques paired with advanced surface treatments, our components ensure tight tolerances and long-lasting quality. This technology supports high-performance operation, essential for industrial machinery and automation systems where reliability and consistency are paramount.

Versatile Industrial Applications

Our mechanical components are tailor-made for integration into CNC milling and turning machines, as well as assembly units. Whether enhancing existing automation systems or powering new builds, they guarantee precise motion transfer and reliable fitting in demanding environments.

Superior Durability and Corrosion Resistance

With anodized and powder coated finishes, each product excels in resisting corrosion and wear. Engineered to withstand pressures up to 16 bar and operate in complex conditions, they deliver considerable longevity and maintain excellent surface quality through repeated use.

FAQs of Engineering Components:

Q: How are these precision mechanical components manufactured?

A: Our components are produced using state-of-the-art CNC machining, which guarantees tight tolerances and superior consistency. Surface treatments like anodizing and powder coating further enhance durability and protect against corrosion, ensuring exceptional performance in industrial settings.Q: What benefits do anodized and powder coated finishes provide?

A: Anodized and powder coated surface treatments significantly increase the components resistance to corrosion and wear. These finishes also improve surface aesthetics and contribute to the overall extended lifespan of the mechanical parts.Q: When should I choose these components for my machinery?

A: Select these components when you require highly accurate (0.01 mm) and durable parts for precise fitting and motion transfer, particularly for industrial machinery, automation systems, and CNC assemblies that operate under varying pressures and conditions.Q: Where can these components be implemented?

A: They are ideal for integration in CNC milling and turning machines, automated assembly units, and other industrial machinery that demands high precision and reliable motion transfer.Q: What is the typical process for ordering and sourcing these components?

A: As a manufacturer, exporter, supplier, and distributor in India, we facilitate swift and streamlined procurement. Clients can contact us directly with their requirements, and we ensure timely delivery backed by technical consultation, if needed.Q: How do these accessories like bearings, shafts, and bushings enhance system performance?

A: These precision accessories play vital roles in reducing friction, guiding motion, and supporting mechanical loads. Their high durability ensures minimal maintenance and reliable operation in high-performance environments.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Engineering Machinery' category

We are offering our products All over India and in Bangladesh, Sri Lanka, Nepal, Bhutan, Middle East, and South Africa.

Send Inquiry

Send Inquiry Send SMS

Send SMS